SWIM LANE DIVIDER VISUAL NUMERICAL ANALYSIS VIA WAVE MACHINE

For this project, the client was a producer of swim-lane dividers, in the industry these are known as queller, because their core functionality is to decrease the size of the waves between swimming lanes in lap pools.

The client wanted a way to quantitatively demonstrate the efficacy of a novel new design. A colleague proposed a system to measure wave height intensity using a a form of electro-conductive tape, but this approach proved non-viable because the response rate of such sensors are very slow.

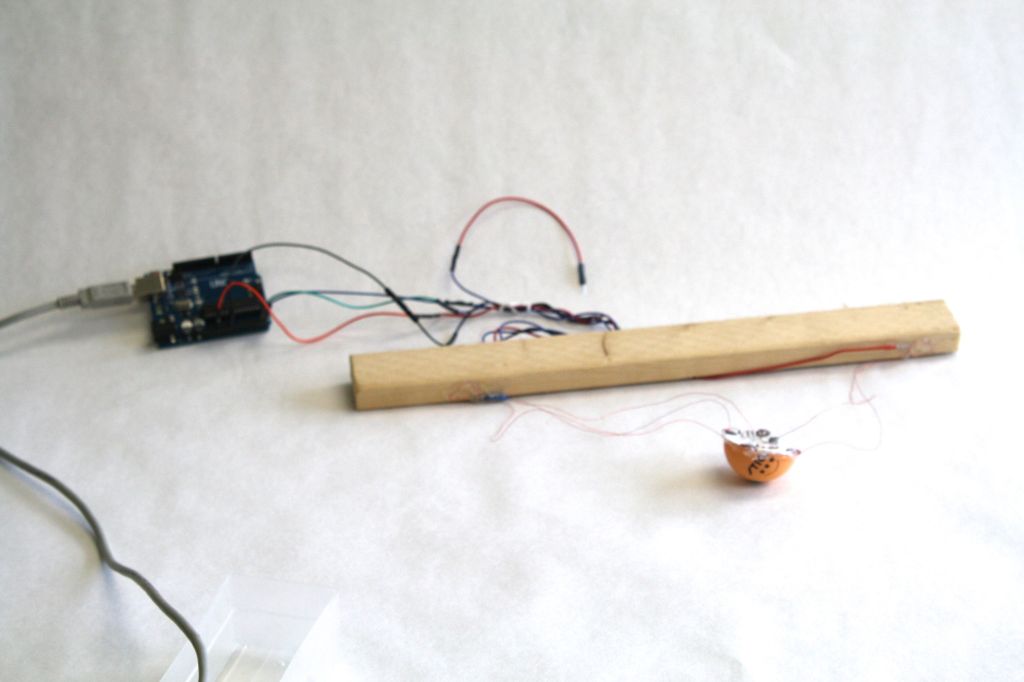

For the first step of the project, I created a proof-of-concept 30-minute prototype, using existing materials on hand, namely, I cut a ping pong ball in half and hot-glued a 3-axis accelerometer in the half ball and suspended it in the wave machine while connected to an arduino.

This prototype demonstrated to my team and client that this approach held promise compared with the proposal that had been previously submitted but proven non-viable. At this point, I became the project lead.

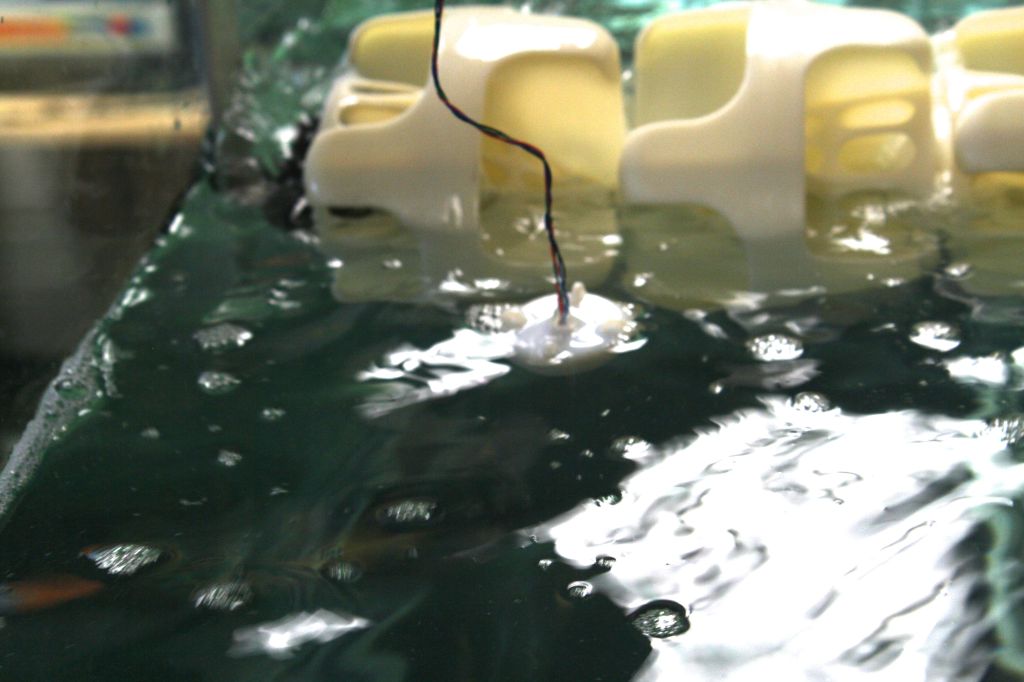

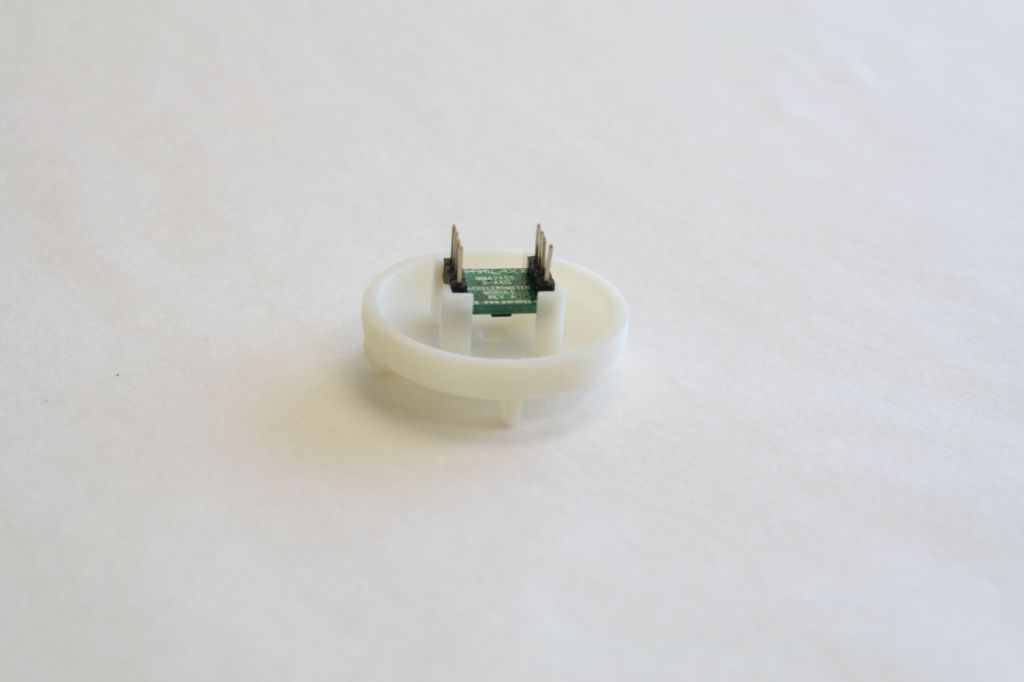

Utilizing CAD software and the Object-30-Prime 3D printers for Stratasys that I was beta testing at the time, I developed the “acorn float”.

A simple housing that could be suspended to float on the surface of the water and measure vertical displacement.

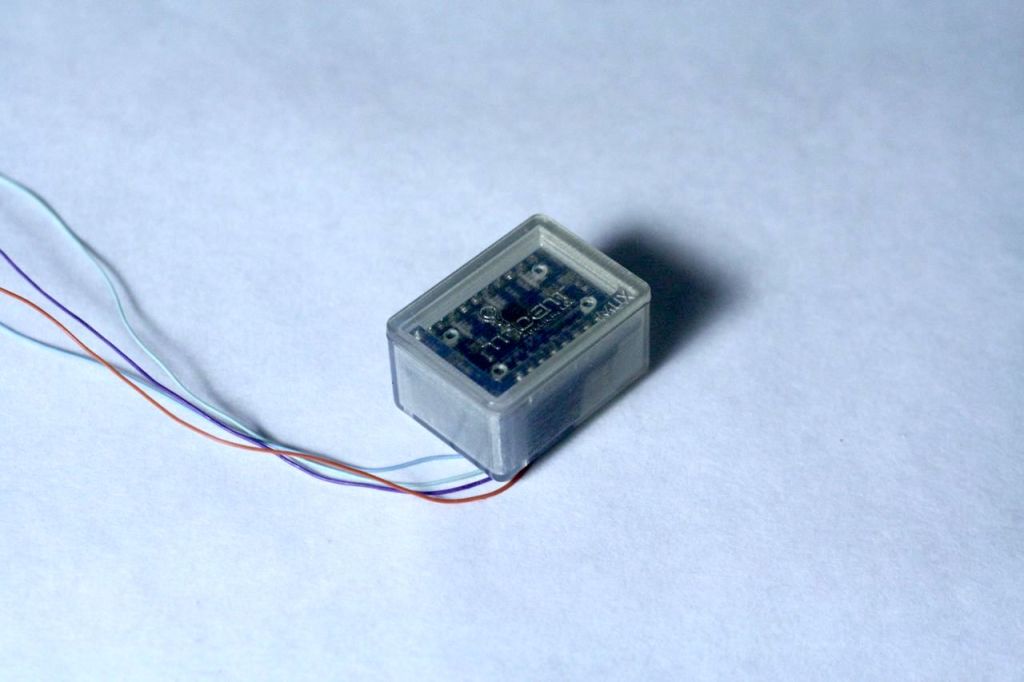

Using an array of 4-acorns with sealed accelerators inside, I created a simple Arduino program to multiplex and log the displacement values.

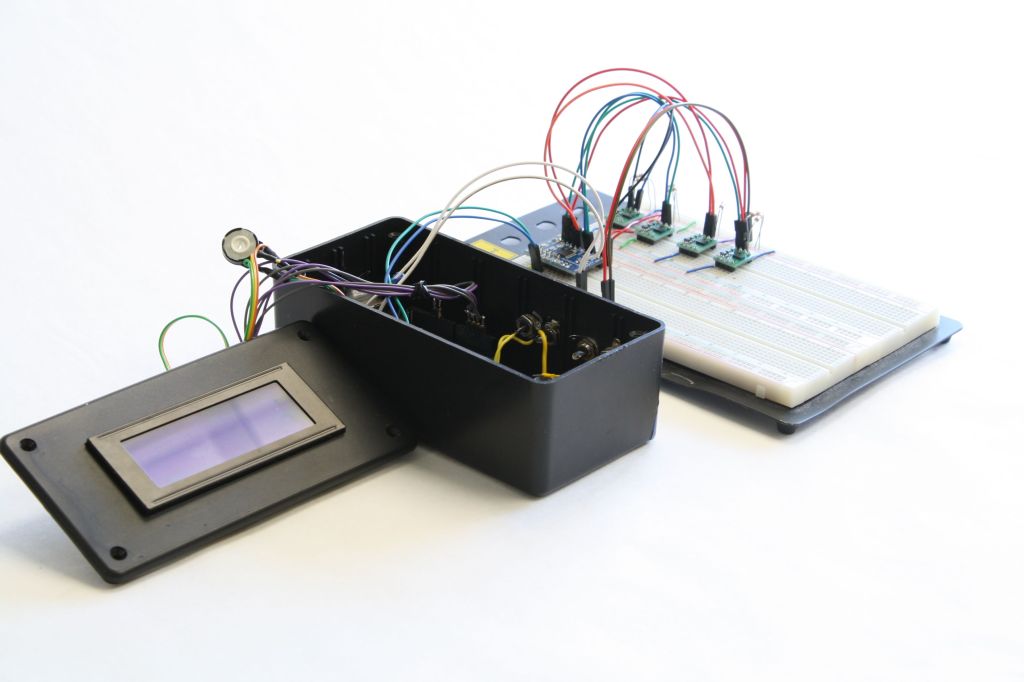

The first step was to create a breadboard prototype of the complete system.

The original concept included only a simple text-based LCD to communicate the vertical-displacement coefficient and provide a numerical analysis of an array of 4-accelerometers, to A/B test side by side versions of various quellers design and print a computed numerical output representing for comparative analysis the z-axis displacements.

UV PEN DISPENSER

This project involved the creation of a physical prototype for an inventor client. My role was to handle all aspects of electronics prototyping. I had the great pleasure of working with an extraordinarily talented designer named Joel (https://www.joelbeebe.com/) who handled all the mechanical engineering and design. We began electronics phase by exploring different technologies for solutions such as detecting the users hand, comparison of motor technology and power requirements, visual indicator devices such as graphic LCD display and LED indicators. We tested multiple prototypes with both feedback and non-feedback motors, ultrasonic and infra-red hand detection methods and a combination of display technologies. The end deliverable is featured below and delivered to the client is a fully functional physical prototype.

AUTOMATIC PEPPER GROW SYSTEM

Increasingly people are becoming interested again in the cultivation of edible plants at home, but there remain many barriers to starting and maintaining this practice. At the industrial agriculture scale, the user of computer monitoring and automation is widespread. However at the small scale consumer level, this technology is still not readily available. This project is an exploration of How might we design a simple, low cost product that for at home consumers to easily grow and maintain very hot pepper plants. The scale of the system is focused on between 1-4 plants.

The basic requirements of the system are light management, water management which is accomplished through timing and sensors. Future work will expand into the domain of nutrient management which is a much more difficult challenge as sensors are prohibitively expensive and require constant calibration to be effective.

HAMMER

This project was concerned with Industrial design of a new hammer concept in the design language of mini cooper.

ART WORK

My form of art work utilizes light as a sculptural element.

This project was exploration of reflection, light and shadow. The form was inspired by the desert Aloe Verde plant.

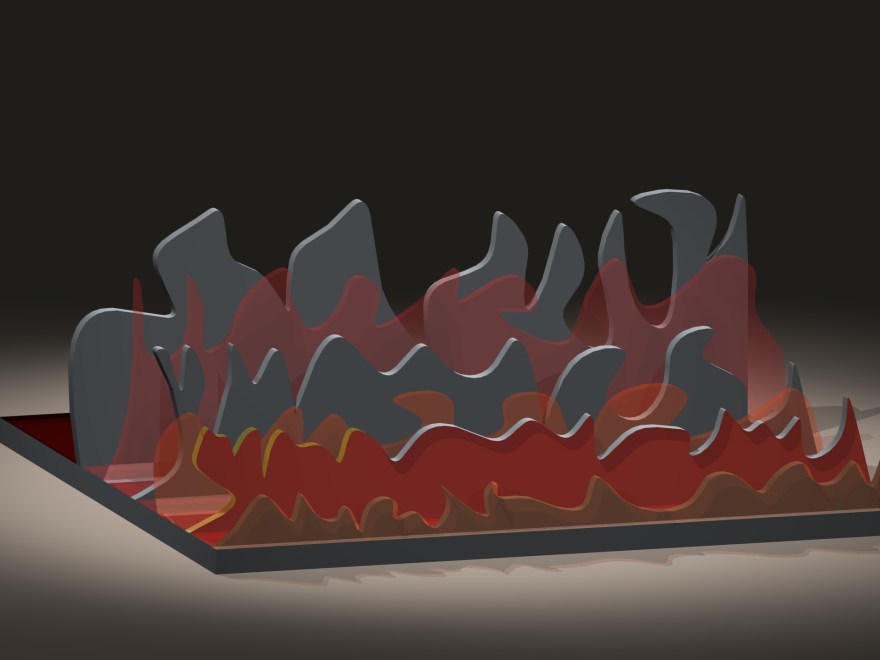

Driving down I-5 between Oregon and California as evening just begins, a famer is burning crops next to the freeway. As darkness falls the light illuminates the clouds of smoke and creates an interesting visual effect. This served as the inspiration for this sculpture, which I first modeled in Solidworks, then laser cut the layers out of acrylic and mounted above an under illuminating light box.

You must be logged in to post a comment.